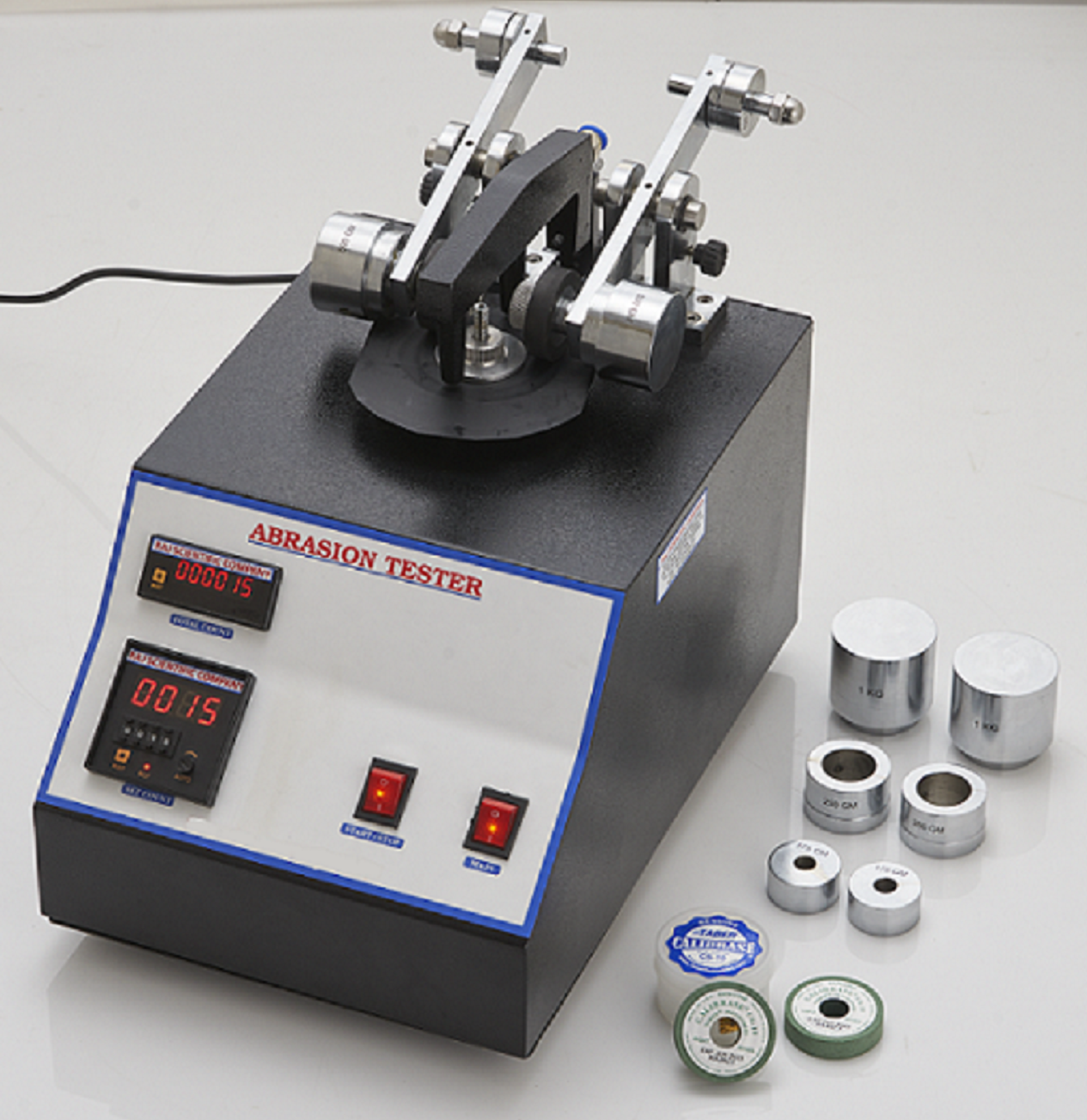

The Taber Abrasion Tester is used to determine the abrasion resistance of organic coatings produced on a plane, rigid surface. The sample panel can be 100 mm diameter disc or 100 × 100 mm square panel with rounded corners and a 6.3 mm center hole. The weighted specimen is mounted on a turntable disc, while the abrasive wheel applies load on the test film. The abrasion resistance varies according to the applied load. This tester is widely used in quality & process control, R&D, and material evaluation across industries such as coatings, textiles, leather, rubber, plastics, wood, glass, paper, laminates, and ceramics. Standards: ASTM D4060, ISO 9352 Key Features: Easy-to-use control panel with Total Count & Batch Count display Vacuum pump system with suction hose for direct flow between hose & rotating disc Release Wheel Hub for quick mounting without tools Balanced calibration arms & wheel mounts with high precision weights Technical Specifications: Platform Speed: 60 ± 2 rpm Auxiliary Weights: 250 gm, 500 gm & 1000 gm (two sets, one per arm) Counterweights: 125 gm & 175 gm (two sets, one per arm) Abrasive Wheels: CS10, CS17 (USA Taber Make – any one) Material: Mild Steel body with durable powder coating; holding arms, counter & auxiliary weights, base disc made of stainless steel. Package Includes: Taber Abrasion Tester Auxiliary weights & counterweights Taber abrasive wheel (CS10) Vacuum pump with suction hose Operation manual Calibration certificate Spares