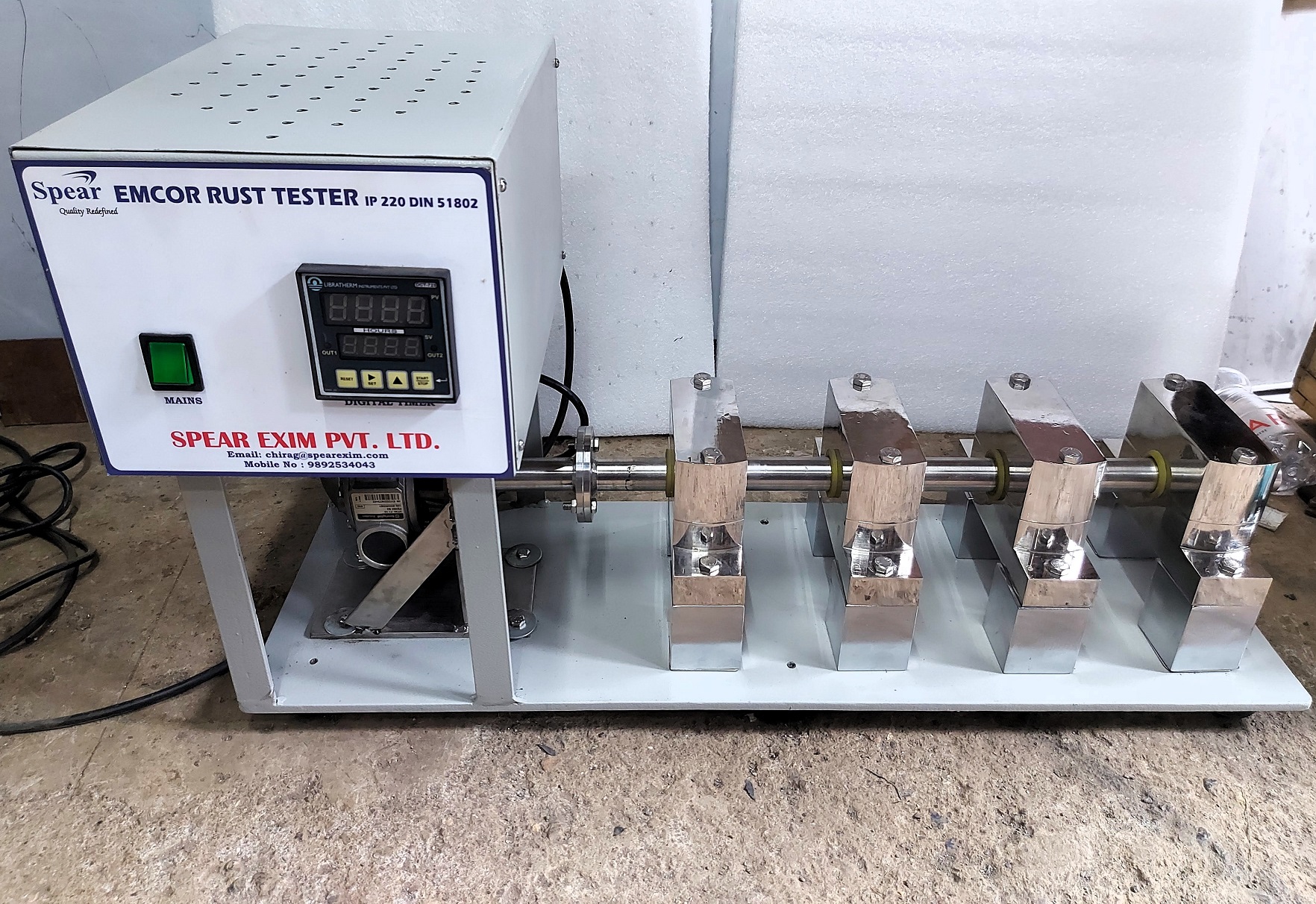

The EMCOR Rust Tester is designed to determine the corrosion-preventive properties of lubricating greases on ball bearings in the presence of water or salt water. The system replicates real-world mechanical and environmental conditions by rotating and resting the bearings in a water medium. It is built to conform with IP 220 , DIN 51802 and ASTM D6138, enabling both dynamic and static corrosion testing of greases. Key Features: 4 / 6 / 8 test setup for testing of bearings simultaneously Bearing housing in SS 316 for high corrosion resistance Powder-coated outer body for long life Operates at 80 RPM with automatic rest/run cycles Includes plummer blocks, adapter sleeves, self-aligning bearings, and V-ring seals Microcontroller-based Run/Rest Timer. Scope of Supply: EMCOR Test Rig with Base Plate Electric Motor with Gear System SS Shaft and Support Assembly Plummer Blocks & Bearing Housings Self-Aligning Bearings Adapter Sleeves & V-Ring Seals Electronic Run/Stop Timer User Manual Applications: Corrosion Testing of Grease in Bearings R&D Labs in Lubricant Industry Grease Quality Control Labs Bearing Testing Facilities Tribology Research Institutes For Pricing and additonal details kindly write or call us.